Introduction to Barcodes and RFID

Barcodes and Radio Frequency Identification (RFID) represent two pivotal technologies widely utilized for inventory management, tracking, and data collection across various industries. Both systems streamline operations and improve the efficiency of gathering and processing data related to products, assets, and even personnel.

Barcodes are composed of a pattern of parallel lines or squares that can be scanned to extract information about an item. Each barcode encodes unique data pertaining to the product such as identification numbers, prices, and descriptions, allowing for quick and accurate data retrieval during the checkout process or inventory audits. Commonly seen in retail environments, barcodes have become ubiquitous due to their low cost and ease of implementation. They rely on optical scanners that read the printed patterns and convert them into machine-readable data.

On the other hand, RFID technology employs electromagnetic fields to automatically identify and track tags attached to objects. Each RFID tag contains a microchip and an antenna, allowing it to communicate wirelessly with RFID readers. This technology can capture data without the need for a direct line of sight, making it superior in situations where quick and automated tracking of multiple items is necessary. As a result, RFID is commonly used in sectors such as logistics, supply chain management, and healthcare, where accuracy and efficiency are critical.

Understanding the differences and applications of these technologies is essential for modern businesses seeking to optimize their operational processes. While barcodes provide a reliable means of product identification, RFID offers advanced features that enhance tracking capabilities. Both systems have their specific advantages and serve particular functions, but collectively they contribute to the overarching goal of improving accuracy in inventory management and data collection.

What Are Barcodes?

Barcodes are machine-readable representations of data, commonly used for tracking and identifying products in various industries, including retail, logistics, and manufacturing. They consist of a series of parallel lines or squares that encode information about the item they represent. The two primary types of barcodes are one-dimensional (1D) and two-dimensional (2D). 1D barcodes, such as Universal Product Codes (UPCs), are the most recognizable, featuring varying widths and spaces that can be scanned using laser-based scanners. In contrast, 2D barcodes, like Quick Response (QR) codes, can store significantly more information by utilizing a matrix of dots, allowing for the encoding of URLs, product details, and even text.

The generation of barcodes involves the use of specific algorithms that convert data into a visual representation that an optical scanner can interpret. For example, when a product is registered in a database, attributes such as its name, price, and quantity are converted into a barcode. This barcode is then printed on product packaging or labels, facilitating the process of scanning during sales, inventory checks, and shipping.

Barcodes offer numerous advantages in business applications. They enhance efficiency by streamlining processes such as checkout, inventory management, and shipping operations. The adoption of barcode technology allows for quick data entry, reducing human error and improving accuracy in tracking goods. However, they also have limitations; for instance, barcodes require line-of-sight scanning and can be rendered unreadable if damaged, obscured, or poorly printed. Furthermore, once a barcode is assigned, its structure is static and cannot be modified without generating a new code. Understanding the strengths and weaknesses of this technology is essential for businesses aiming to optimize their operations and adapt to the ever-evolving landscape of retail and logistics.

What Is RFID?

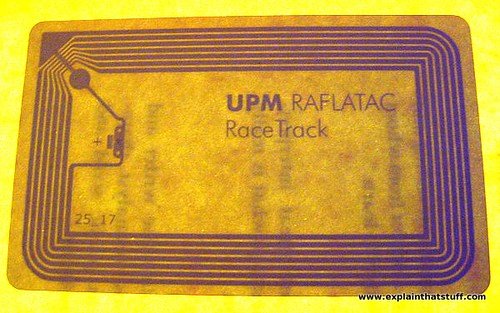

Radio-frequency identification (RFID) is an advanced technology that utilizes electromagnetic fields to automatically identify and track tags attached to objects. An RFID system typically consists of three main components: RFID tags, RFID readers, and antennas. RFID tags, which can be either passive or active, contain unique identifiers and are capable of storing data about the item they are attached to. Passive RFID tags rely on energy emitted by the reader to function, while active RFID tags include a built-in battery that powers the device, allowing for a greater range of communication.

RFID readers, or interrogators, send out radio waves to communicate with the RFID tags within their range. The tags respond by sending back their stored information, which the reader converts into digital data that can be processed by computer systems. Antennas serve as the bridge between the RFID tags and readers, facilitating the transmission of signals. The technology’s non-line-of-sight operation allows for multiple tags to be read simultaneously, enhancing efficiency in processes where swift identification is crucial.

RFID technology is widely deployed across various industries due to its versatility and efficiency. In supply chain management, RFID facilitates real-time tracking of inventory, ensuring that products are readily available and improving overall logistics. In access control systems, RFID is used for secure entry to buildings or restricted areas, often replacing traditional keycards. Additionally, in asset tracking, RFID can monitor valuable items, equipment, and even personnel, providing organizations with detailed insights into their resources. The adoption of RFID has revolutionized how industries operate, promoting increased accuracy and reduced overhead costs.

Comparison of Functionality

When examining the functionality of barcodes and RFID (Radio-Frequency Identification), a few key factors warrant discussion, including data storage capacity, scan range, and speed, as these attributes greatly influence their effectiveness in varying scenarios.

Barcodes, which are commonly seen on retail products, hold limited data capacity. Typically, a standard 1D barcode can store up to 20 characters of information, while 2D barcodes can contain a few hundred characters. This data is often restricted to identifying the item linked to a particular stock-keeping unit (SKU) or product identifier. Conversely, RFID technology offers a significantly higher data storage capacity; RFID tags can contain thousands of characters, allowing for much more comprehensive information including operational history and product details.

Another major difference is their scanning range. Barcodes require a direct line of sight for scanners to capture the information, making them less efficient for large-scale operations or when items are crowded. The scan range of a barcode is typically limited to within a few inches, thus requiring close proximity. RFID, on the other hand, can transmit data over a range of several feet, and in some cases even longer. This enables faster scanning in bulk settings, such as warehouses or distribution centers, where time and efficiency are paramount.

Speed is another critical aspect of functionality where RFID outshines barcodes. RFID systems can read multiple tags at once, substantially reducing the time taken to track inventory. In contrast, barcode scanning usually involves a serial scanning process, which can lead to delays, especially in scenarios requiring the scanning of numerous items at once. Thus, in environments such as retail checkout or inventory management where speed and accuracy are crucial, RFID technology presents a distinct advantage over traditional barcodes.

Cost Analysis

When comparing barcodes and RFID, one of the most critical factors to consider is the cost associated with each technology. Both systems require an initial investment, along with ongoing maintenance costs, but the breakdown of these expenses can vary significantly.

The initial setup costs for a barcode system typically include purchasing barcode printers, scanners, and software for inventory management. A barcode label printer may range from a few hundred to several thousand dollars, depending on the required durability and printing capabilities. Scanners are available in various models, with basic handheld versions being less expensive than advanced stationary units. Furthermore, software licensing fees may apply, which could range from a few hundred to several thousand dollars annually, depending on the complexity of the system.

In contrast, RFID systems generally involve higher initial costs. The primary expenses come from RFID readers, antennas, and RFID tags. RFID readers can range from several hundred to several thousand dollars, influenced by their range and capabilities. The cost of RFID tags, which contain the data, can also be significant, especially for active tags that have a longer lifespan and greater data storage. Additionally, implementing RFID requires software tailored to integrate with existing warehouse management systems, which can further increase upfront costs.

Despite the higher initial costs associated with RFID, it is crucial to analyze the long-term value and return on investment (ROI) both technologies offer. RFID provides efficiencies in inventory management, reduces labor costs, and improves accuracy in tracking items, leading to long-term savings. Barcodes, while generally more affordable initially, may result in higher operational costs due to manual scanning processes and potential human error. Ultimately, businesses must evaluate their specific needs and the anticipated volume of transactions to determine which system provides the best financial solution in the long term.

Precision and Accuracy

When comparing barcodes and RFID (Radio Frequency Identification) systems, it is essential to evaluate their precision and accuracy within different environments and conditions. Barcodes, which are primarily optical representations of data, rely on direct line-of-sight scanning. This requirement often poses challenges in scenarios where barcodes are damaged, dirty, or poorly aligned, leading to scanning errors. Human interaction can also introduce variability; for instance, incorrect scanner angles or operators’ inconsistencies can result in misreads or failed scans. Consequently, while barcodes work effectively for certain applications, their precision can diminish in environments that do not favor optimal visibility.

RFID technology, on the other hand, operates on radio waves and does not necessitate a direct line of sight for data transmission. This characteristic significantly enhances its performance in environments where barcodes might struggle. RFID tags can be read through materials such as plastic and cardboard, making them more versatile in tracking assets that are in tight storage situations. Moreover, RFID systems have the ability to read multiple tags simultaneously, thereby improving efficiency in data collection. This capability allows RFID to minimize human error, as operators can scan entire pallets or groups of items at once, significantly reducing the reliance on manual input.

However, while RFID demonstrates enhanced accuracy in challenging conditions, it is not without its own limitations. Environmental factors, such as interference from metals or liquids, can affect the performance and range of RFID signals. Despite these potential issues, RFID generally maintains a higher reliability rate in data transmission and collection, especially in dynamic or high-volume environments. Thus, organizations seeking improved precision and accuracy in inventory management and asset tracking must weigh the specific advantages of each system to determine the most appropriate solution for their operations.

Security Measures and Data Integrity

Both barcodes and RFID technology have distinct security features, yet each exhibits vulnerabilities that can impact their effectiveness. The reliance on visual scanning and line-of-sight in barcode systems exposes them to counterfeit risks. Barcodes can easily be replicated or modified, rendering them susceptible to fraud. Furthermore, once a barcode is printed, it cannot be altered without physically replacing it, which can be a significant drawback when attempting to maintain accurate data over time.

In contrast, RFID technology affords a more robust security structure. RFID tags contain microchips that store data and communicate with readers through radio waves. This capability allows for the implementation of encryption methods to safeguard information transferred between RFID tags and readers. However, RFID systems are not exempt from threats; unauthorized access remains a concern. There exists a risk of eavesdropping, where individuals scan RFID signals without consent or knowledge, potentially compromising sensitive data.

To mitigate these vulnerabilities in both systems, organizations should adopt best practices focused on data integrity and secure transactions. For barcodes, implementing unique serialization for each code can help deter counterfeiting. Regular audits and updates of the barcode database further enhance security by ensuring that any discrepancies are quickly identified. For RFID technology, utilizing secure communication protocols, such as Advanced Encryption Standard (AES), along with regularly updating encryption keys, can significantly protect against unauthorized access.

Moreover, employing tamper-evident labels for both barcodes and RFID tags can aid in detecting unauthorized alterations to the product or its associated data. By combining technological safeguards with stringent procedural measures, businesses can enhance the overall reliability and security of their inventory management systems, effectively addressing the complexities associated with both barcode and RFID technology.

Future Trends in Tracking Technologies

As businesses increasingly seek efficiency in inventory management and item tracking, the evolution of tracking technologies such as barcodes and RFID is becoming increasingly vital. In the coming years, we can expect to see significant advancements in both fields, driven by emerging applications and innovations that leverage the Internet of Things (IoT), artificial intelligence (AI), and big data analytics.

One notable trend is the integration of IoT technology with tracking systems. This convergence allows for real-time data collection and analysis, enabling businesses to monitor inventory levels and item locations with unprecedented accuracy. IoT devices can gather data from RFID readers or barcode scanners and transmit this information to centralized databases, enhancing decision-making processes and inventory visibility. As the infrastructure for IoT expands, we anticipate greater adoption of these integrated systems across various industries, streamlining operational efficiency.

Innovations in data management are also shaping the future of tracking technologies. Enhanced data analytics capabilities will enable organizations to derive meaningful insights from the data collected via barcodes and RFID systems. Predictive analytics can be leveraged to forecast inventory needs, optimize supply chain logistics, and mitigate potential disruptions, ultimately leading to improved customer satisfaction. The combination of RFID and sophisticated data management tools is expected to elevate tracking methodologies beyond traditional capabilities.

Furthermore, developments in machine-readable technologies will likely introduce more advanced scanning devices that enhance the speed and accuracy of inventory tracking. Technologies such as QR codes may see increased use alongside traditional barcodes, providing businesses with an expanded array of tracking options that cater to diverse requirements. This diversification of tracking technologies reflects a growing trend toward flexibility and adaptability in item management.

As the landscape of tracking technologies continues to evolve, it is clear that barcodes and RFID will remain at the forefront of innovations, with emerging trends poised to revolutionize the way organizations manage their inventory and enhance operational efficiencies.

Conclusion: Choosing the Right Technology

When deciding between barcodes and RFID for inventory management and tracking systems, it is essential to understand the fundamental differences between these two technologies. Barcodes are widely recognized for their simplicity and cost-effectiveness. They consist of printed lines that need to be scanned with a laser or camera-based reader. While the initial investment costs for barcode systems are relatively low, they require direct line-of-sight scanning, which can become a limitation in certain environments.

On the other hand, RFID technology utilizes radio waves to transmit data between a reader and tags embedded in products. This enables automatic identification and tracking of items over a broader range and does not require direct line-of-sight. Although RFID systems tend to have a higher upfront investment and are more expensive than traditional barcodes, their benefits in terms of efficiency and accuracy may justify the costs in the long run.

In choosing the appropriate technology for a business, several factors should be considered, including the specific industry needs, budget constraints, and anticipated return on investment. For industries that require real-time inventory tracking, such as retail or logistics, RFID might offer significant advantages. Conversely, businesses with smaller-scale operations or limited budgets may find barcodes adequately meet their needs.

Ultimately, the decision should be guided by a thorough evaluation of each technology’s strengths and weaknesses, aligning them with the strategic goals of the organization. By conducting an impact analysis and perhaps even piloting both systems, businesses can make informed choices that elevate their operational efficiency while catering to their unique requirements.

© barcodly.com- All rights reserved