Introduction to ISO Standards

ISO standards, established by the International Organization for Standardization, provide a framework for ensuring quality, safety, and efficiency across various industries worldwide. These standards serve as internationally recognized guidelines that facilitate trade, enhance product quality, and improve overall operational efficiency. By adhering to ISO standards, organizations can assure customers of the reliability and consistency of their products and services.

The relevance of ISO standards in international trade and commerce cannot be overstated. They help eliminate barriers to trade by ensuring that products meet agreed-upon criteria, fostering consumer trust and promoting fair competition. By standardizing processes, materials, and technology, companies can enhance interoperability in supply chains, supporting seamless global transactions. This reliability is especially vital in sectors such as manufacturing, healthcare, and information technology, where compliance with ISO standards can significantly influence business outcomes.

Furthermore, the development and publication of ISO standards involve a collaborative process that includes experts from various stakeholder groups, including industry professionals, government agencies, and consumer representatives. This inclusiveness ensures that the resulting standards reflect practical insights and accommodate diverse needs. The process begins with the identification of a need for a standard, leading to extensive deliberations and consensus-building efforts to formulate a draft. Once agreed upon, the draft is subjected to public inquiry before it is finalized and published.

Ultimately, the significance of ISO standards goes beyond regulatory compliance; they embody a commitment to quality improvement and operational excellence. By understanding the role of ISO standards, organizations can leverage these guidelines not only to enhance their competitive edge but also to foster a culture of continuous assessment and improvement across their operations.

The Importance of Barcode Quality

In today’s fast-paced retail and supply chain environments, the significance of barcode quality cannot be overstated. High-quality barcodes are essential for ensuring the efficiency and accuracy of operations, which directly impacts an organization’s bottom line. Poor-quality barcodes can lead to scanning errors, causing delays and inaccuracies in inventory management. When barcodes are not printed clearly or are damaged, scanners may fail to read them properly, resulting in misplaced items or erroneous data entry.

These errors often manifest as inventory discrepancies that can hinder the ability to track stock levels accurately. In a retail setting, inaccurate inventories can result in stockouts or overstock situations, both of which adversely affect customer satisfaction and trust. The inability to quickly and efficiently fulfill customer orders can ultimately lead to a loss of revenue. Furthermore, in an era where supply chain efficiency is crucial for competitiveness, businesses cannot afford the consequences of poor barcode quality.

Moreover, the importance of barcode quality extends beyond just immediate financial implications; it encompasses broader operational integrity and brand reputation. Stakeholders, including customers and suppliers, rely on the accuracy of systems that utilize barcode technology. Regular assessments and adherence to established ISO standards for barcode quality can mitigate the risks associated with poor barcodes, promoting a smoother flow of goods and services throughout the supply chain.

In conclusion, maintaining high standards of barcode quality is indispensable for organizations aiming to optimize their supply chain processes. Implementing comprehensive quality measures not only reduces the likelihood of scanning errors but also safeguards profitability and enhances overall operational efficiency.

Overview of Barcode Standards

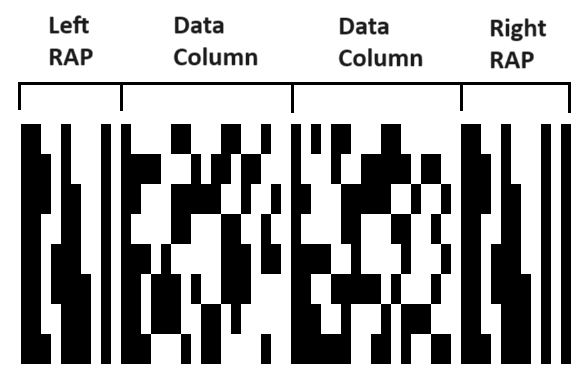

Barcode standards are essential for ensuring that barcodes can be universally read and interpreted across various systems and devices. The International Organization for Standardization (ISO) plays a crucial role in developing these standards, creating a framework that aids in the interoperability of barcode systems globally. Among the prominent bodies contributing to barcode development is GS1, whose guidelines have become a gold standard in this field.

One of the most recognized barcode formats is the Universal Product Code (UPC), which is commonly used in retail environments to uniquely identify products. UPC barcodes are defined by specific ISO standards, ensuring that they can be scanned and recognized by point-of-sale systems without errors. Another notable format is the Quick Response (QR) code, a two-dimensional barcode that has gained popularity due to its ability to store more information than traditional one-dimensional codes. QR codes are versatile and can effectively link to digital content, making them suitable for marketing and advertising applications.

In addition to UPC and QR codes, ISO outlines several other barcode formats, including Code 128 and Code 39, each designed for various applications and industries. Code 128 is known for its high-density encoding and is frequently utilized in shipping and packaging. Conversely, Code 39 is often employed in inventory management for its simplicity and ease of use.

Each of these barcode formats complies with specific ISO standards, facilitating efficient data capture and accurate product identification. By adhering to these guidelines, businesses can ensure that their barcode systems contribute to operational efficiency and reduce the likelihood of errors during data entry or inventory management.

ISO/IEC 15416: The Key Standard for Barcode Quality

ISO/IEC 15416 is a crucial standard aimed at ensuring the quality and reliability of barcodes across diverse applications. This standard primarily addresses two key areas: print quality metrics and scanning performance requirements. Understanding the parameters outlined in ISO/IEC 15416 is essential for organizations that rely on barcode technology to streamline operations and improve accuracy.

One of the critical aspects examined in ISO/IEC 15416 is the print quality of barcodes. This section evaluates factors such as contrast, resolution, and the overall appearance of the barcode. By adhering to the specifications set forth by this standard, businesses can ascertain that the barcodes printed on products are clear and easily readable by scanning devices. These quality metrics help minimize scanning errors and improve the overall efficiency of the supply chain.

In addition to print quality, ISO/IEC 15416 assesses scanning performance requirements. This aspect focuses on the ability of barcode scanners to accurately read barcodes across various conditions, including lighting variations and distance. The standard provides guidelines on how scanning devices should be tested and what benchmarks they must meet to ensure consistent performance. By understanding these requirements, organizations can invest in appropriate scanning technologies that align with the standards, thus enhancing their operational effectiveness.

Ultimately, ISO/IEC 15416 serves as a benchmark for assessing barcode quality, ensuring that barcodes remain readable and reliable. Through the implementation of this standard, businesses can significantly reduce errors associated with barcode scanning, leading to enhanced operational excellence. Adopting the principles outlined in ISO/IEC 15416 not only elevates barcode quality but also boosts the reliability of entire systems that rely on this technology, thus exemplifying its critical role in modern commerce.

Measurement Methods for Barcode Quality

Evaluating barcode quality is essential for ensuring operational efficiency and accuracy within various industries, especially those heavily reliant on automated systems. Several measurement methods and tools are employed to assess barcode performance, each contributing to a comprehensive understanding of quality metrics.

Visual inspection remains one of the foundational techniques for measuring barcode quality. This method involves a qualified individual examining the barcode for defects such as blurring, size inconsistencies, or any damage that may affect readability. Visual inspection is often supplemented by subjective assessments of contrast, which refers to the difference in color between the bars and spaces of the barcode. High contrast is critical, as it enhances the clarity and visibility of the code under various lighting conditions.

Automated scanning is another vital measurement method used to evaluate barcode quality. Dedicated barcode scanners or image-based scanners assess various performance metrics such as magnification, which determines whether the barcode can be scanned at different sizes. This capability is essential in environments where distances between the scanner and barcode vary. Furthermore, automated systems can measure decode capability, indicating whether the barcode can be accurately deciphered by different types of scanners. This capability is crucial for ensuring compatibility, especially in multi-vendor environments.

Other metrics that contribute to thorough barcode quality assessments include the speed of decoding and error rates. Each of these parameters plays a significant role in the operational efficiency of systems that rely on barcode technology for inventory management, tracking, and many other applications. By understanding and implementing these measurement methods, organizations can ensure that their barcode systems function optimally, reducing errors and enhancing overall productivity.

Practical Applications of ISO Standards in Industries

ISO standards play a vital role in ensuring barcode quality across various industries, leading to enhanced operational efficiencies and improved accuracy. Retail, logistics, and manufacturing are among the key sectors where adherence to these standards has proven beneficial. By implementing ISO barcode standards, businesses can ensure that their products are easily identifiable and trackable, which is essential for maintaining inventory accuracy and streamlining supply chains.

In the retail sector, for instance, the use of ISO-compliant barcodes facilitates smooth transactions at checkout counters. A prominent case study involves a leading global retailer that experienced a 30% increase in checkout speeds after transitioning to ISO standards for their barcodes. This improvement not only heightened customer satisfaction due to reduced wait times but also decreased the instances of errors during sales transactions, reflecting the importance of barcode quality in the retail environment.

Similarly, in logistics, effective barcode utilization governed by ISO standards enhances tracking capabilities. A logistics company adopted ISO-compliant barcodes to monitor the movement of packages throughout their distribution network. This implementation resulted in a 15% reduction in lost packages and heightened their overall operational efficiency. By ensuring that each package is accurately scanned and accounted for, businesses can drastically cut down operational errors, leading to better resource allocation and timely deliveries.

In the manufacturing industry, ISO standards for barcodes contribute to quality control and traceability. A prominent manufacturer incorporated ISO-standard barcoding on its assembly line to track parts and components. This practice not only improved the accuracy of inventory counts but also expedited the recall process in the event of defective products. Ultimately, this illustrates how ISO standards bolster operational performance, cost-effectiveness, and product quality across industries.

Challenges in Maintaining Barcode Quality

Barcode quality is critical for businesses that rely on accurate product identification and inventory management. However, several challenges can impede the consistent maintenance of barcode quality. One significant issue is environmental factors, which can adversely affect the readability and longevity of barcodes. For instance, printing barcodes in high-humidity areas can lead to smudging or blurring, while exposure to direct sunlight can cause fading. Furthermore, physical damage, such as scratches or dirt accumulation, can dramatically decrease barcode scannability. To combat these challenges, businesses must take environmental conditions into account when designing their packaging and printing processes.

Another challenge arises from equipment limitations. Many organizations utilize outdated or suboptimal printing technology, which can result in poorly printed barcodes that do not meet industry standards. Inconsistent printer settings or low-quality ink can lead to variations in barcode appearance, causing scanning errors down the line. Implementing regular maintenance checks and investing in higher-quality printing technologies can greatly enhance barcode quality. Organizations should also ensure that their scanning devices are capable of reading the various formats of barcodes they might encounter to avoid any discrepancies.

Human error constitutes a further challenge in maintaining barcode quality. Workers may inadvertently mislabel products, input incorrect data into inventory systems, or improperly handle barcode scanners. Providing comprehensive training and creating a culture of quality awareness among employees are essential steps in minimizing human error. Continuous improvement processes should be adopted, where feedback loops enable organizations to identify prevalent issues and implement corrective measures. By addressing these challenges, businesses can significantly enhance their barcode quality, ultimately leading to improved efficiency and accuracy in their operations.

Best Practices for Ensuring High Barcode Quality

Ensuring high barcode quality is critical to maintaining the efficiency and accuracy of data capture systems. The initial design and ongoing maintenance of barcodes play a significant role in their effectiveness. A robust approach to barcode quality begins with proper design principles, such as selecting the appropriate barcode type that aligns with the specific application requirements. It is essential to consider factors like data density, scanning distance, and environment when choosing the right barcode format.

Correct printing techniques are paramount in achieving barcode quality. Businesses should utilize high-resolution printers specifically designed for barcode creation. It is advisable to use the recommended materials, including high-quality paper or synthetic labels, to prevent wear and tear that can affect scannability. Additionally, barcode printers should be regularly maintained to ensure optimal performance; that includes changing printing elements as needed and conducting routine checks on ink or toner levels.

Effective training for personnel involved in the barcode process cannot be overstated. Employees should be educated on the importance of barcode quality and familiarized with scanning requirements. Training should encompass best practices for barcode handling and application, such as ensuring barcodes are properly placed on products with sufficient white space around them to enhance readability. Moreover, staff should understand potential pitfalls that can lead to barcode degradation, including exposure to moisture, extreme temperatures, or physical damage.

Lastly, conducting regular quality audits is vital in sustaining high barcode quality. These audits should evaluate the readability of existing barcodes in the operational environment and identify areas for improvement. Implementing a system for continuous feedback and quality checks can promote ongoing diligence in barcode management. By adhering to these practices, businesses can foster optimal barcode performance, ensuring their systems operate with maximum efficiency and accuracy.

Conclusion and Future Trends in Barcode Standards

Adhering to ISO standards for barcode quality is crucial for ensuring efficiency and accuracy in various industries. These standards not only enhance readability and reliability but also facilitate seamless data interchange across different systems. As global commerce expands and supply chains become more complex, the significance of maintaining barcode quality through established ISO standards cannot be overstated. This compliance is vital for minimizing errors in inventory management, enhancing customer satisfaction, and ultimately fostering a competitive edge in the marketplace.

Looking ahead, several emerging trends are shaping the future of barcode technology and standards. The advent of advanced technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is driving innovations in barcode applications. These technologies enable real-time tracking and monitoring of products, thereby improving operational efficiencies and response times. The integration of barcodes into mobile devices and applications is also on the rise, making it easier for businesses to access critical data instantly.

Moreover, as more industries adopt automation and digitization strategies, the need for standardized barcode systems becomes more pronounced. This necessity is further emphasized by the development of new barcode formats, such as two-dimensional (2D) barcodes and QR codes, which offer enhanced data capacity and functionality. The standardization of these formats is essential to ensure interoperability and consistency across various platforms and devices.

As barcode technologies continue to evolve, industry stakeholders must remain vigilant in their commitment to adhering to ISO standards for barcode quality. By doing so, they will not only ensure operational efficiency and accuracy but also stay ahead of emerging trends that will shape the future of barcoding systems. This proactive approach is vital for sustaining growth and adaptability in an increasingly dynamic business environment.

© barcodly.com- All rights reserved