Introduction to Barcodes in Dropshipping

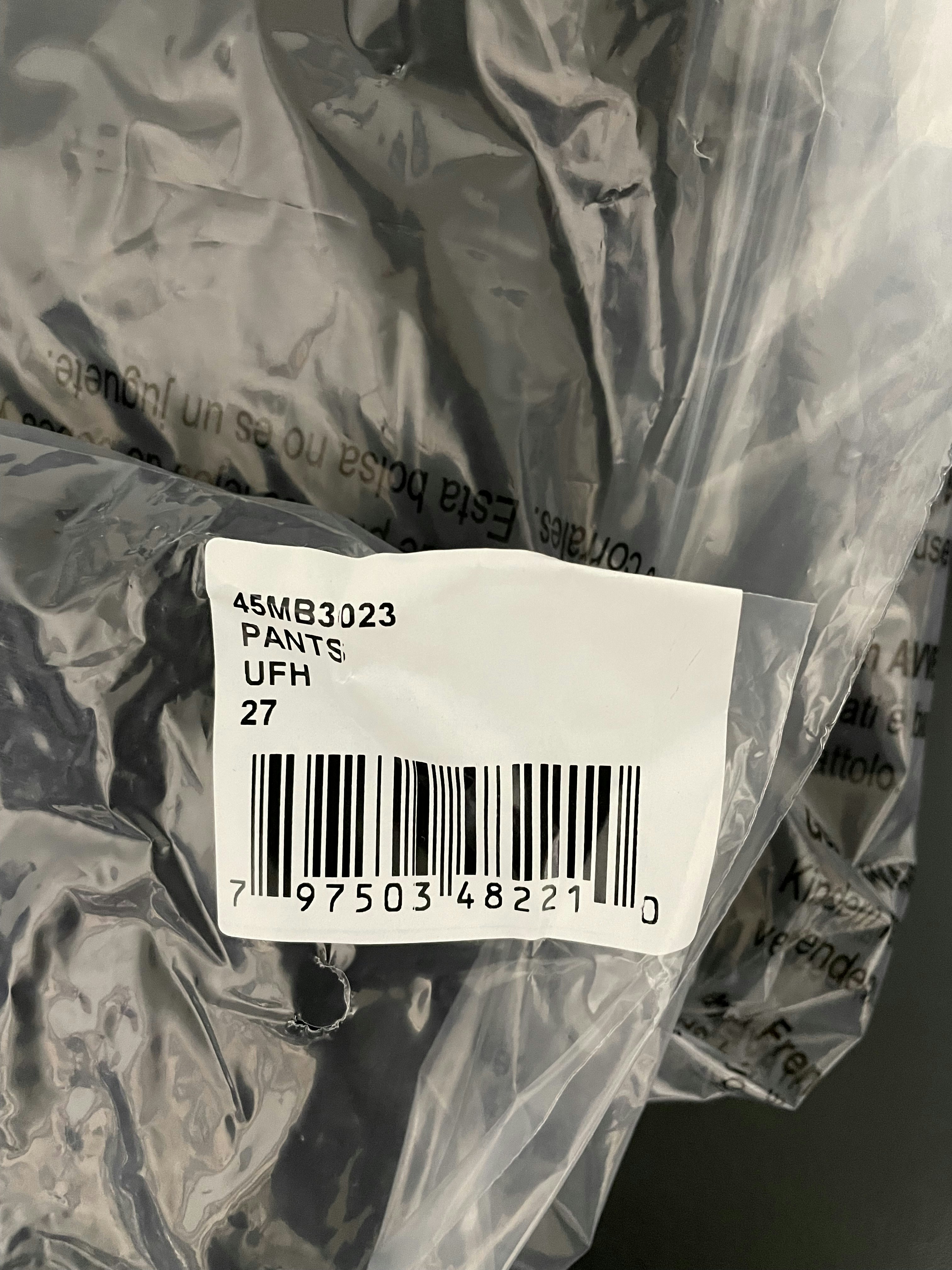

Barcodes have become an integral element in the world of dropshipping, serving as critical tools for both inventory management and product tracking. A barcode is a machine-readable representation of data that typically consists of a series of vertical bars and spaces, which can be scanned by a barcode reader. This technology allows businesses to encode information about a product such as its SKU (Stock Keeping Unit), price, and description, enabling efficient management of stock levels and order fulfillment processes.

In the context of dropshipping, where inventory is not held by the retailer but rather shipped directly from the supplier to the customer, the role of barcodes becomes even more pronounced. They facilitate accurate tracking of products as they move through the supply chain. Each time a product is scanned, the corresponding information is automatically updated in the system, reducing the likelihood of human error and ensuring that accurate data is maintained regarding stock availability and shipment status.

The implementation of barcodes also streamlines the shipping process for dropshippers. By using barcodes, sellers can quickly and accurately identify products that need to be shipped, minimizing the time spent on each order. This efficiency not only enhances customer satisfaction due to quicker fulfillment times but also improves overall operational efficiency, making the business more competitive in a crowded marketplace.

Moreover, barcodes provide essential insights into inventory turnover rates and sales trends, empowering dropshippers to make informed decisions regarding product selection and stock replenishment. As the dropshipping sector continues to evolve, understanding the functionality and benefits of barcodes remains vital for success. This foundational knowledge sets the stage for navigating the complexities of dropshipping and optimizing operational processes.

Understanding Different Types of Barcodes

Barcodes are essential tools in the dropshipping industry, serving as machine-readable representations of data that streamline product identification and inventory management. Various types of barcodes are utilized, each designed for specific applications based on their unique characteristics and benefits. Among the most widely used are Universal Product Codes (UPC) and European Article Numbers (EAN).

The Universal Product Code (UPC) is primarily employed in North America and consists of 12 digits. This type of barcode is commonly found on consumer products and is designed for quick identification at point-of-sale systems. UPC barcodes are beneficial for dropshippers as they provide a universally recognized format that simplifies inventory tracking and sales data analysis.

Another prevalent barcode format is the European Article Number (EAN), which can be either EAN-13 or EAN-8, depending on the length of the code. EAN-13, with its 13 digits, is commonly used for retail products outside North America. The EAN system is particularly advantageous for dropshippers targeting international markets, facilitating easier shipments and compliance with local regulations.

In addition to UPCs and EANs, Quick Response (QR) codes have gained popularity due to their versatility and ease of use. QR codes store a significant amount of information and can be scanned using smartphones, providing quick access to product details, promotional content, or websites. For dropshippers, incorporating QR codes can enhance customer engagement and streamline the shopping experience.

Other barcode types, such as Code 128 and Code 39, are also available and offer different functionalities suited to varying operational needs. Understanding these barcode types and their applications is crucial for dropshippers in selecting the appropriate system that aligns with their business requirements and enhances overall efficiency.

How Barcodes Enhance Inventory Management

Barcodes play a crucial role in modern inventory management systems, particularly within the dropshipping business model. By utilizing barcodes, businesses can streamline inventory counts, improve accuracy, and enhance overall operational efficiency. The use of barcodes significantly reduces the time required for manual inventory counting, enabling quick and reliable scanning of products. This is especially beneficial in a dropshipping environment where inventory levels often fluctuate, necessitating up-to-date tracking.

The implementation of barcode systems allows for seamless tracking of product movements, from the moment an order is placed to its final delivery. Each product is assigned a unique barcode that can be scanned, providing real-time visibility into stock levels and locations. This level of tracking is essential in preventing stockouts, ensuring that businesses can fulfill customer orders promptly, without delays that might result from inventory mismanagement.

Furthermore, barcodes help in mitigating errors that are commonplace in manual inventory processes. Human errors can occur during stock takes or when recording product information; however, barcode scanning minimizes these risks by automating the process. As a result, the accuracy of inventory data increases substantially, leading to better decision-making when it comes to restocking and managing supply chains.

Incorporating barcode technology into your inventory management system not only enhances the efficacy of tracking inventory but also allows businesses to focus more on scaling their operations. The ability to monitor inventory in real-time provides dropshipping companies with the insights necessary to adjust their strategies and respond to market demands efficiently. Overall, adopting barcode solutions is a significant step towards optimizing inventory management in dropshipping, ultimately contributing to improved operational performance.

Implementing Barcodes in Your Dropshipping Business

Implementing barcodes in your dropshipping business is essential for streamlining operations and ensuring efficient inventory management. A systematic approach can facilitate this process, enhancing order fulfillment and accuracy. Here’s a step-by-step guide to effectively incorporate barcodes into your business model.

The first step involves generating unique barcodes for each product. You can use various online barcode generators or software that comply with industry standards such as UPC or EAN formats. Ensure that each barcode is distinct to avoid confusion during inventory management. It is advisable to print these barcodes on labels that can be affixed to products securely, ensuring they remain scannable throughout the shipping and handling process.

Next, integrate the barcodes with your inventory management software. Many platforms offer built-in support for barcode scanning, allowing you to track products more efficiently. When setting up your system, ensure that each barcode corresponds to the correct item in your inventory, which will facilitate tracking stock levels and streamline reordering processes.

Once your barcodes are linked with your inventory management system, you’ll want to incorporate them into your order fulfillment process. During packing, scan each item’s barcode to verify that the correct products are included in shipments. This step not only reduces errors but also speeds up the shipping process, improving customer satisfaction.

Finally, train your team on the importance of using barcodes effectively. A knowledgeable staff can help maintain an organized workflow and minimize mistakes. Encourage regular audits to ensure that the barcode system remains operational and effective. By following this framework, you can efficiently implement barcodes in your dropshipping enterprise, leading to optimized operations and better customer service.

The Importance of Barcode Scanners

In the rapidly evolving landscape of dropshipping, the role of barcode scanners cannot be overstated. These devices have become integral to the efficiency, accuracy, and overall success of order processing. Barcode scanners come in various types, including handheld, fixed, and mobile scanners, each serving specific functions that cater to the needs of dropshipping businesses.

Handheld barcode scanners are designed for flexibility, allowing operators to easily move around warehouses or retail spaces to scan products. This mobility not only speeds up the inventory management process but also enhances the accuracy of order fulfillment. By eliminating manual data entry, businesses reduce the risk of errors, ensuring that customers receive the correct products in a timely manner. Furthermore, handheld scanners often come with advanced features, such as Bluetooth connectivity and compatibility with various operating systems, enabling seamless integration with shipping software or inventory management systems.

Fixed barcode scanners, typically installed at strategic locations such as checkout areas or packaging stations, provide a stationary solution for high-speed scanning. These devices can quickly read multiple barcodes in succession, contributing to fast processing times during peak hours. Their ability to automate data capture minimizes human intervention, further enhancing accuracy and improving the overall workflow within distribution centers.

Mobile barcode scanners offer the unique advantage of combining portability with advanced functionalities, such as built-in data storage and connectivity to the internet or company networks. This allows dropshipping businesses to perform real-time inventory tracking and order management from anywhere in the supply chain. By utilizing mobile solutions, companies can quickly respond to fluctuations in demand and maintain optimal stock levels, ensuring efficient operations.

In this way, barcode scanners play a crucial role in the dropshipping process. Their functionality contributes not only to enhanced speed and efficiency but also to the precise management of inventory and order fulfillment, ultimately leading to improved customer satisfaction.

Challenges of Using Barcodes in Dropshipping

While barcodes play a critical role in the efficiency of dropshipping operations, they also present a range of challenges that businesses must navigate. One of the primary issues faced is barcode misreads. This can occur due to various factors including poor printing quality, damaged labels, or scanner malfunctions. When a barcode is misread, it can lead to incorrect inventory management, resulting in customers receiving the wrong products or orders being delayed. To mitigate this issue, businesses should invest in high-quality printing systems and regularly test scanners to ensure accurate readings.

Another significant challenge lies in the lack of standardization within the barcode systems employed by different suppliers. Many dropshippers work with multiple suppliers who may utilize different barcode formats or systems. This inconsistency can complicate inventory management as products may not be easily identifiable across various systems. To address this challenge, it is advisable for dropshippers to establish clear communication with suppliers and to adopt universal barcode standards whenever possible, ensuring that all products can be uniformly scanned and tracked.

Furthermore, the dynamic nature of dropshipping requires that systems are updated regularly. As suppliers change their product offerings or update existing inventory, barcodes may also need to be revised. Failure to update barcode data promptly can result in discrepancies that can disrupt operations. To overcome this challenge, dropshippers should implement robust inventory management software that integrates directly with supplier databases, enabling real-time updates and minimizing the risk of outdated information affecting order fulfillment.

Overall, understanding and addressing these challenges associated with barcode usage in dropshipping is essential for maintaining effective inventory management and ensuring customer satisfaction.

Barcode Compliance and Regulation

In the dropshipping industry, adherence to barcode compliance and regulation is crucial for maintaining operational efficiency and legality. Several organizations establish guidelines that businesses must follow to ensure their barcodes meet industry standards. One of the most recognized bodies in this domain is GS1, which provides a global framework for the identification of products through barcodes. GS1 standards are designed to improve supply chain efficiency and enhance traceability, making them indispensable for dropshippers.

Compliance with GS1 regulations entails obtaining a unique Global Trade Item Number (GTIN) for each product. This number is essential for creating barcodes that retailers, warehouses, and customers can easily read and process. It is also important to note that each barcode must be registered correctly to avoid duplication or misuse, which could lead to significant losses and compliance issues. Non-compliance can result in penalties, disruptions in supply chains, or even the inability to sell products through major retail channels, which highlights the importance of maintaining proper barcode practices.

Additionally, the necessity for compliance extends to various sectors, such as food safety and pharmaceuticals, where regulations are particularly stringent. In these industries, barcodes contribute to tracking and tracing products throughout the supply chain, ensuring that businesses can recall products swiftly in the event of a safety issue. Therefore, understanding and implementing these regulations is not merely a matter of best practices; it is a legal obligation that can greatly impact a business’s credibility and operational success.

Ultimately, meticulous attention to barcode compliance and regulatory standards will enable dropshipping businesses to thrive in a competitive marketplace. Such diligence fosters trust among consumers and enhances the overall integrity of the dropshipping model.

Using QR Codes for Dropshipping Efficiency

The integration of QR codes into the dropshipping model has emerged as a significant trend, differentiating itself from traditional barcode systems. Unlike traditional barcodes, which typically contain limited data and require a scanner to retrieve information, QR codes can store much more information and can be scanned using a smartphone camera. This capacity enhances the efficiency of dropshipping operations and provides unique marketing opportunities.

Businesses that leverage QR codes effectively can enhance their marketing strategies. For instance, by embedding QR codes onto product packaging or promotional materials, they can direct customers to their websites, special offers, or product videos. This not only fosters greater customer engagement but also allows businesses to track the success of their marketing initiatives in real-time. Moreover, QR codes can streamline the buying process—customers can quickly access their cart or checkout page, reducing potential friction during the purchase process.

Additionally, QR codes offer operational advantages within the dropshipping supply chain. For example, suppliers can use QR codes to provide real-time inventory updates to dropshippers. By scanning these codes, businesses can instantly access vital supply chain information, leading to better stock management and order fulfillment strategies. This capability helps minimize the risk of overselling or stockouts, which are common challenges in the dropshipping business model.

Furthermore, enhancing customer engagement is another area where QR codes can prove invaluable. Dropshipping businesses can create interactive experiences by encouraging customers to scan QR codes for rewards, surveys, or feedback forms. These initiatives not only build a relationship with customers but also yield important data for continuous improvement. As the dropshipping landscape evolves, the intelligent use of QR codes will likely play a pivotal role in driving efficiency and engagement.

Future Trends: The Evolution of Barcodes in E-commerce

The future of barcodes within the dropshipping and e-commerce sectors appears promising, driven by rapid technological advancements that are reshaping how products are tracked and managed. One of the most significant developments is Radio Frequency Identification (RFID) technology, which is increasingly being adopted as an alternative to traditional barcodes. RFID systems utilize electromagnetic fields to automatically identify and track tags attached to objects. This advancement allows for real-time monitoring of inventory, markedly improving efficiency in warehouse operations and fulfillment processes.

As e-commerce continues to grow, so does the complexity of managing large inventories and ensuring accurate tracking of goods. The integration of RFID not only accelerates inventory audits but also minimizes human errors associated with barcode scanning. By transitioning to RFID systems, dropshipping businesses can gain better insight into stock levels, enhancing decision-making capabilities related to restocking and seasonal trends. Moreover, RFID tags can be read without the need for line-of-sight scanning, which streamlines the process of inventory management.

Further evolution in the barcode landscape also includes the incorporation of mobile technologies. With smartphones becoming indispensable tools for both consumers and businesses, the ability to scan and process barcodes via mobile applications is critical. This shift supports a more agile supply chain, where dropshippers can quickly assess product availability and pricing, ensuring that their offerings remain competitive. Additionally, the development of advanced data analytics tied to barcode scanning will provide deeper insights into consumer behavior and inventory trends.

In conclusion, the future of barcodes in e-commerce and dropshipping is characterized by technological innovations that facilitate enhanced product tracking and inventory management. Businesses that embrace these advancements will likely maintain a competitive edge, ensuring efficiency and responsiveness to market demands.

© barcodly.com- All rights reserved