Introduction to Expiry Date Tracking

Effective inventory management is critical across various sectors, particularly for industries dealing with perishable goods such as food, pharmaceuticals, and cosmetics. Tracking expiry dates is an essential aspect of this process, as it directly impacts consumer safety and product quality. Products that surpass their expiry dates can lead to serious health risks, including foodborne illnesses, adverse drug reactions, and skin irritations. Consequently, the ramifications of not adhering to expiry date protocols can result in significant financial losses for businesses, stemming from waste, product recalls, and potential legal liabilities.

In the food industry, expired goods can compromise nutritional value and safety, leading not only to health concerns for consumers but also damaging a brand’s reputation. Similarly, pharmaceuticals that are used beyond their shelf life may lose potency or pose risks due to chemical degradation. In the cosmetics industry, using expired products can result in adverse skin reactions, thus exemplifying the necessity for stringent tracking procedures. Therefore, implementing an efficient expiry date tracking system is imperative for ensuring consumer safety, maintaining product efficacy, and preserving brand integrity.

Modern solutions to this challenge involve leveraging technology, such as barcode systems, that streamline inventory management processes. By utilizing barcodes, businesses can enhance accuracy in tracking expiry dates, ensuring timely stock rotation and minimizing the likelihood of expired products being sold to consumers. The integration of barcode technology into inventory systems not only promotes operational efficiency but also provides the assurance that customers receive safe and high-quality products. Ultimately, the need for effective expiry date management is paramount in safeguarding public health and sustaining business viability.

Understanding Barcodes: The Technology Behind Tracking

Barcodes are a prevalent technology used in various industries to streamline processes, enhance efficiency, and improve accuracy in inventory management. Essentially, a barcode is a machine-readable representation of data, which is typically visually encoded in the form of parallel lines and spaces of varying widths. The primary purpose of barcodes is to encode information that can be quickly read and processed by a scanner. There are various types of barcodes, including traditional UPC (Universal Product Code) and more advanced options like QR (Quick Response) codes. Each type serves distinct purposes within inventory systems.

Traditional UPC codes consist of 12 digits, and they uniquely identify products sold through retail channels. The structure of a UPC includes a series of black and white vertical lines—each line’s width and spacing correspond to the numeric data represented. This allows for quick scanning at checkout registers or inventory checkpoints, facilitating the management of stock and sales data. On the other hand, QR codes are two-dimensional barcodes that can hold a significantly larger amount of information when compared to UPC codes. They encode data in both vertical and horizontal formats, making them versatile for various applications, including tracking expiry dates in perishable goods.

The scanning process is essential for the functionality of barcodes. When a barcode scanner reads a barcode, it utilizes a laser or an imaging system to capture the pattern of lines. This pattern is then translated into digital data, which can be used to access detailed information about the item, such as its name, price, and in the case of expiration tracking, its shelf life. This integration of barcode technology in inventory management systems simplifies the process of keeping track of product expiry dates, thereby ensuring that consumers receive quality products while allowing retailers to optimize stock levels effectively.

Combining Barcodes with Expiry Date Information

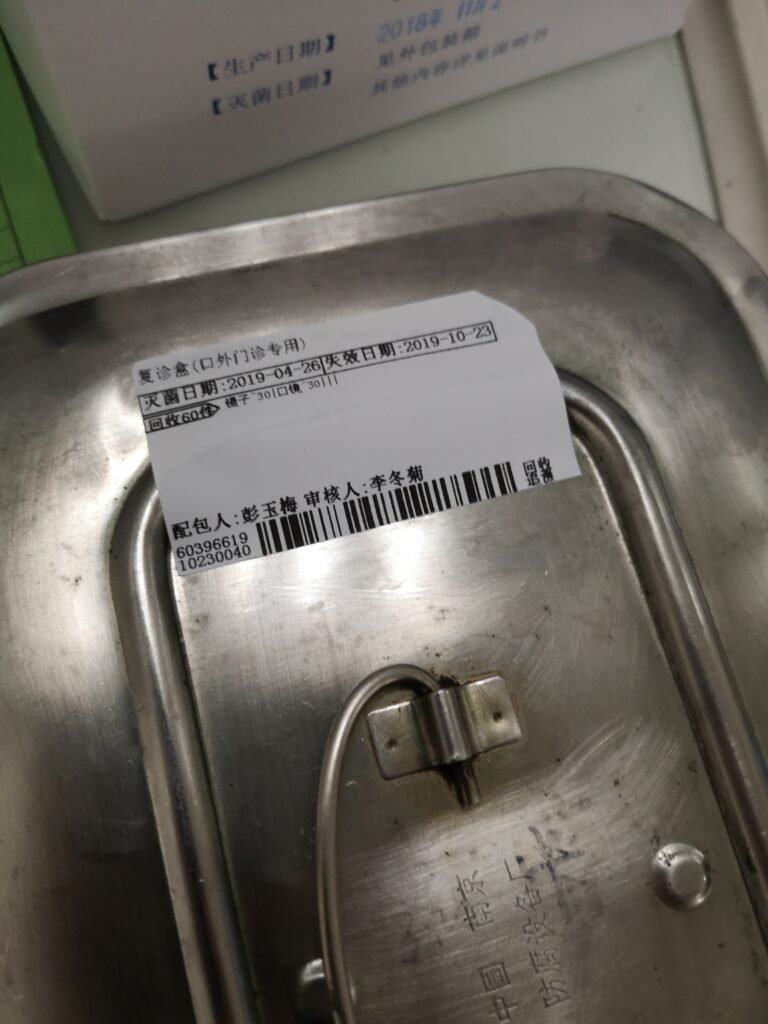

Barcodes have become an integral part of modern inventory management, significantly improving efficiency and accuracy. By incorporating expiry date information directly into barcodes, organizations can streamline tracking and reduce the likelihood of using or selling expired products. This integration involves encoding expiry dates within the barcode itself, a process made feasible through various encoding methods.

One common way to embed expiry dates in barcodes is by utilizing the Global Trade Item Number (GTIN) or Universal Product Code (UPC) formats. In these systems, manufacturers can allocate specific numbers or characters that represent the expiry date, effectively linking it with the product’s unique identifier. Other formats, such as QR codes or Data Matrix codes, provide greater flexibility by allowing for more extensive data storage. This flexibility enables businesses to include not only the expiry date but also additional product information, such as batch numbers or manufacturing dates.

To facilitate barcode generation and management, numerous software solutions are available on the market. These applications allow users to create barcodes that include both product identification and expiry date data. Furthermore, they often feature accessible interfaces that enable quick updates should the expiry information change, ensuring real-time accuracy in inventory records. By employing robust software, businesses can ensure that their barcode systems remain consistent and reliable.

The advantages of storing expiry information alongside product identification cannot be understated. This method enhances inventory control, enabling companies to track when products are due to expire easily. Automated alerts can notify staff to remove products nearing expiry from shelves or to prioritize their sale. As a result, businesses can minimize wastage, improve customer satisfaction by ensuring fresh products, and ultimately enhance the overall management of their inventory.

Benefits of Using Barcodes for Expiry Date Management

Employing barcodes for managing expiry dates offers numerous advantages that enhance inventory management processes significantly. One of the primary benefits is increased accuracy. Barcodes facilitate quick and precise scanning, reducing the likelihood of human errors that can arise from manual data entry. This elevated accuracy ensures that inventory records reflect real-time stock levels and expiry dates, aiding in effective decision-making for businesses.

In addition to accuracy, using barcodes also leads to reduced human error. Manual inventory counts and tracking can be fraught with mistakes, particularly in environments with a high volume of products. Barcodes mitigate this risk by automating the tracking process. For example, retail chains that have implemented barcode systems have reported substantial decreases in discrepancies between actual stock levels and recorded data. This reduction in errors can ultimately improve customer satisfaction by ensuring that products remain in optimal condition.

Enhanced efficiency in stock rotation is another significant benefit. Barcodes allow for a streamlined process of monitoring shelf life, making it easier to implement first-expiry-first-out (FEFO) principles. This efficient stock rotation minimizes wastage due to expired products. Businesses that operate with perishable goods, such as supermarkets or restaurants, can especially benefit from this system, as it helps maintain product freshness and quality.

Moreover, utilizing barcodes for expiry date management improves compliance with health regulations. Industries such as food and pharmaceuticals are subject to strict regulations regarding inventory control and expiry tracking. Barcodes simplify this process by enabling businesses to demonstrate compliance through accurate record-keeping and efficient tracking practices. A case in point can be seen in pharmaceutical companies, where barcode systems have been pivotal in complying with industry standards, ensuring that expired products are promptly removed from shelves, thereby safeguarding consumer health.

Case Studies of Barcode Usage in Various Industries

Barcode technology has transformed various industries, enhancing their ability to manage expiry dates effectively. In the food services sector, numerous restaurants and grocery chains have adopted barcode systems to track inventory. For instance, a leading supermarket chain implemented a barcode tracking system that enabled their staff to scan products at the point of receiving shipments. This practice significantly minimized waste by alerting employees when perishable items were nearing their expiry dates, thereby facilitating timely sales or removal from shelves. As a result, the chain improved food safety and reduced operational costs associated with expired products.

In the retail industry, clothing brands have also benefited from barcode tracking. By integrating barcodes into their inventory management, they have gained real-time visibility into stock levels and expiry dates for seasonal items. A notable clothing retailer implemented a barcode system that allowed for quicker restocking and reduced markdowns on products close to expiry. This system not only enhanced customer satisfaction by ensuring that popular items were readily available but also preserved profit margins by reducing clearance sales on unsold, aging stock.

The pharmaceutical industry showcases a crucial application of barcode tracking, particularly in managing medication expiry dates. Many healthcare providers have adopted sophisticated barcode systems to maintain accurate records of drug inventory. For instance, a hospital pharmacy deployed a barcode scanning solution to track the shelf life of various medications. This enabled pharmacists to monitor expiry dates effectively and automatically generate alerts for impending expirations, thus ensuring patient safety and compliance with regulations. Consequently, the pharmacy improved its operational efficiency while minimizing the risk of administering expired medications.

Finally, the logistics sector has embraced barcode technology to streamline inventory management processes. By employing barcodes on shipments, logistics companies can track inventory throughout the supply chain effectively. A major logistics firm reported that using barcode scanning for tracking expiry dates significantly reduced errors in inventory records and enhanced overall productivity. This implementation not only saved time but also ensured compliance with safety regulations across the industry, illustrating the value of barcode technology in managing expiry dates.

Challenges and Limitations of Barcode Tracking Systems

Despite the numerous advantages that barcode tracking systems offer for managing expiry dates in inventory, there are significant challenges and limitations that organizations need to consider. One of the primary challenges is scanner compatibility. Various types of barcode scanners exist, and not all scanners can read every type of barcode, leading to potential discrepancies in inventory tracking. This incompatibility may necessitate additional expenditures for organizations if they must upgrade their existing scanners to accommodate different barcode formats.

Another critical limitation is the vulnerability of barcode labels. Barcodes can be subject to damage, fading, or obstruction due to environmental factors. For instance, labels might be exposed to moisture or excessive temperatures that can spoil the print quality. Such damage can result in scenarios where barcodes become unreadable, hindering the ability to accurately track expiry dates and potentially leading to spoilage of inventory. To combat this, businesses should invest in durable label materials and protective coatings that enhance resistance to various elements.

Reliance on software systems is another element of concern. Barcode tracking systems often depend on integrated software to function effectively. Any malfunctions, updates, or data corruption in the software can disrupt the entire tracking process. Organizations should be aware of these vulnerabilities and ensure they have reliable IT support to maintain their systems. Additionally, it’s essential to conduct regular backups to prevent data loss. Training staff on both the hardware and software aspects of barcode systems can also mitigate potential issues.

In summary, while barcode tracking systems for expiry dates are effective, businesses must remain vigilant about the challenges they pose. By addressing issues such as scanner compatibility, label durability, and software reliability, companies can enhance their inventory management processes and minimize potential drawbacks.

Best Practices for Implementing Barcode Expiry Date Tracking

Implementing a barcode expiry date tracking system can significantly enhance inventory management for businesses. To ensure the successful adoption of this technology, it is essential to follow certain best practices that align with operational needs and workforce capabilities.

First, selecting the right software is crucial. Look for inventory management solutions that specifically support barcode tracking functionality. The software should allow for easy integration with existing systems, provide user-friendly interfaces, and offer robust features for tracking expiry dates. This not only streamlines operations but also helps in maintaining efficient records throughout the product lifecycle.

Secondly, adequate training for staff is imperative. Employees should be well-versed in how to use barcode scanners, interpret data, and understand the significance of expiry date tracking. Regular training sessions can improve accuracy and reduce errors in inventory management, leading to more reliable results over time. Consider developing a comprehensive training program that includes hands-on exercises to enhance practical skills.

Label placement plays a pivotal role in the effectiveness of barcode tracking. Barcodes should be affixed in easily accessible locations on products for quick scanning. Ensure that the labels are durable and resistant to wear and tear, particularly in environments where they may be exposed to extreme conditions. Proper placement will facilitate faster inventory turnover and reduce the chances of expired products being overlooked.

Moreover, conducting regular audits is beneficial. Implement a schedule for routine checks on expiry dates and inventory levels to ensure compliance with established procedures. Utilizing barcode technology allows businesses to quickly identify and address any discrepancies, thereby minimizing risks associated with expired items.

Finally, seamless integration with existing inventory management systems will maximize the efficacy of barcode expiry date tracking. By consolidating data and ensuring that all systems communicate effectively, businesses can gain deeper insights into stock control and make informed decisions. Adopting these best practices can lead to improved operational efficiency and reduced product waste.

The Future of Expiry Date Tracking: Trends and Innovations

As businesses increasingly recognize the importance of effective inventory management, the future of expiry date tracking is poised to undergo significant transformations driven by technological advancements. One major trend is the integration of the Internet of Things (IoT), which facilitates real-time monitoring of products. By employing IoT-enabled devices, companies can automate the tracking of expiry dates, alerting staff to items approaching expiration. This integration not only enhances efficiency but also significantly reduces waste, ensuring that only products with sufficient shelf life reach consumers.

Artificial Intelligence (AI) is another area predicted to revolutionize expiry date management. Machine learning algorithms can analyze vast datasets to provide insights on inventory turnover rates, consumer purchasing behaviors, and optimal stock levels. Such predictive analytics enable businesses to strategically manage their inventories, ensuring that products are sold or used before they expire. By predicting trends and identifying patterns, AI can enhance decision-making processes related to stock replenishment and expiration date management.

Enhanced barcode systems are also being developed to improve expiry date tracking. Traditional barcodes are giving way to more sophisticated solutions, such as QR codes and RFID tags. These advanced systems not only store more information regarding a product, including its expiry date, but also facilitate swift access to data. This capability allows for seamless integration with inventory management software, streamlining the overall tracking process. Companies can scan products quickly, receive alerts about expiry dates, and take proactive measures to minimize losses.

Ultimately, the convergence of IoT, AI, and advanced barcode technology signifies a shift toward a more efficient and reliable system for tracking expiry dates. As these innovations continue to evolve, the management of product lifecycles will become increasingly refined, enhancing both operational efficiency and consumer safety in the marketplace.

Conclusion: Embracing Barcode Tracking for Enhanced Safety and Efficiency

As highlighted throughout this blog post, the implementation of barcode tracking in inventory management stands as a fundamental strategy for businesses striving to ensure the safety and well-being of their consumers. Barcode technology streamlines the monitoring of product expiry dates, facilitating timely interventions that prevent the sale of expired goods. This proactive approach not only contributes to consumer safety but also enhances operational efficiency, safeguarding businesses against potential liabilities associated with expired inventory.

The integration of barcode systems promotes accuracy in inventory tracking, empowering businesses with real-time data on stock levels and product status. This capability allows for more informed decision-making regarding restocking and managing expiring items, significantly reducing the risks associated with human error. As a result, not only does barcode tracking minimize waste and financial loss, but it also fosters a culture of responsibility towards both consumer safety and sustainable practices.

Moreover, as companies continue to adapt to technological advancements, embracing barcode tracking can serve as a competitive advantage in today’s market. Organizations that prioritize the implementation of such systems can effectively build consumer trust, affirming their commitment to providing quality products. In an age where consumers are increasingly becoming aware of the importance of product safety, businesses that utilize barcode technology to maintain up-to-date inventory records can distinguish themselves from competitors who rely on outdated methods.

In conclusion, investing in barcode tracking is not merely an operational upgrade; it is a crucial step towards enhancing product safety and ensuring the satisfaction of consumers. Businesses are encouraged to consider the integration of barcode systems into their inventory management practices. Such an investment can lead to streamlined processes, improved accuracy, and a steadfast commitment to consumer protection. Embracing this technology represents a forward-thinking strategy that aligns with the demands of modern inventory management.

© barcodly.com- All rights reserved