Introduction to Multi-Warehouse Operations

Multi-warehouse operations refer to the practice of managing several warehouse locations within a company’s supply chain. This framework is significant in modern supply chain management as it allows organizations to enhance distribution efficiency, optimize inventory levels, and better meet customer demands. In an increasingly globalized market, businesses are compelled to adopt multi-warehouse strategies to leverage geographical advantages, respond quickly to market needs, and improve service delivery.

Operating multiple warehouses introduces certain complexities that must be effectively managed. One of the primary challenges is coordinating operations across various locations. Each warehouse may have distinct characteristics, such as size, layout, and the types of products stored. This diversity necessitates tailored approaches in terms of inventory management, staffing, and logistics. Moreover, discrepancies in data across warehouses can hinder efficiency and lead to challenges in maintaining accurate stock levels, resulting in potential overstocking or stockouts.

Efficient inventory management becomes crucial in multi-warehouse environments. Companies need to ensure that each warehouse is stocked appropriately to meet localized demand without incurring excess holding costs. This requires robust inventory tracking systems that provide real-time visibility into stock levels across all locations. Furthermore, logistics coordination is vital to assure timely deliveries and minimize transportation costs. Optimizing routes and implementing systematic processes can enhance productivity and reduce delivery times across the network.

To address these challenges effectively, many businesses leverage advanced technology solutions such as barcode systems. These systems streamline inventory tracking and improve data accuracy, alleviating many hurdles associated with multi-warehouse operations. The integration of such technologies facilitates informed decision-making, ultimately contributing to the overall efficiency of the supply chain.

Understanding Barcode Systems

Barcode systems play a critical role in modern warehouse operations, providing an efficient method for tracking inventory and streamlining processes. At a basic level, a barcode is a machine-readable representation of data that translates into a series of numeric or alphanumeric characters. When scanned, this data reveals specific information about a product or item, enabling real-time inventory management. There are two main categories of barcodes: one-dimensional (1D) and two-dimensional (2D). The former, commonly used in retail applications, consists of vertical lines that vary in width, making them easy to scan with laser scanners. 1D barcodes include formats such as UPC and Code 39.

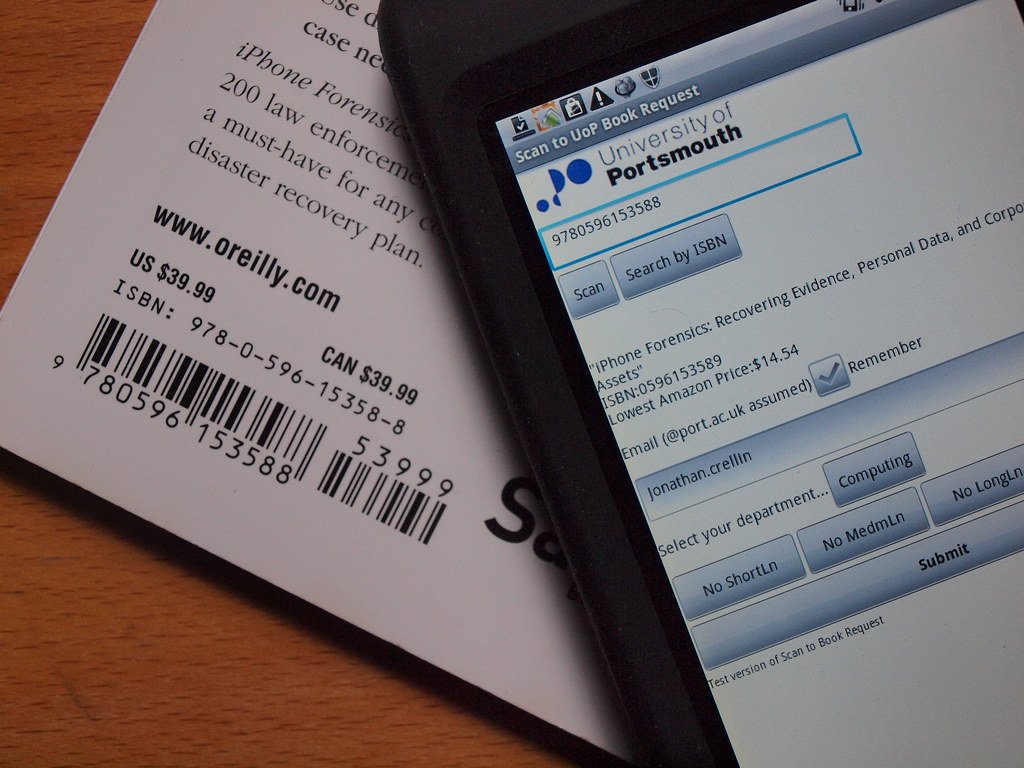

On the other hand, 2D barcodes, including QR codes, can store significantly more information due to their matrix structure. They can encompass a wide range of data points, such as URLs, product details, and even contact information. This expanded capacity is especially beneficial in warehouse operations where quick access to detailed information is critical. To leverage barcode systems effectively, warehouses utilize various scanning devices, including handheld scanners, stationary scanners, and mobile devices equipped with camera technology.

The integration of barcode systems into Warehouse Management Systems (WMS) has revolutionized inventory accuracy and operational efficiency. Software applications in a WMS utilize barcode data to automate tasks, such as stock counting and reorder notifications. The synergy between hardware and software in barcode systems ensures seamless communication, significantly reducing human error that often accompanies manual entries. Overall, understanding barcode systems and their workings is essential for optimizing multi-warehouse operations, fostering seamless inventory management, and ultimately enhancing productivity.

Benefits of Implementing Barcode Systems in Multi-Warehouse Operations

Implementing barcode systems in multi-warehouse operations offers numerous advantages that significantly enhance operational efficiency. One of the primary benefits is improved inventory accuracy. Traditional manual inventory processes are prone to human error, which can lead to discrepancies and misplaced stock. Barcode systems facilitate automatic data capture, ensuring that each item is scanned and recorded accurately, thereby reducing the incidence of errors and improving overall inventory records.

Another notable advantage is the reduction in labor costs. With barcode systems, the time required for inventory management activities is substantially decreased. Tasks that previously took hours, such as counting and recording stock, can be completed in a fraction of the time through quick scanning. This efficiency allows staff to redirect their efforts towards more productive activities, thus driving down overall labor expenses in multi-warehouse environments.

Enhanced order fulfillment speed is yet another benefit that barcode systems bring to the table. In a multi-warehouse operation, quick and accurate order processing is essential to meet customer expectations. Barcodes streamline the picking and packing processes by allowing workers to quickly locate and identify products. This expedited order fulfillment not only improves customer satisfaction but also boosts the overall throughput of the warehouse operations.

Moreover, barcode systems provide better tracking of products across various locations, which is critical in multi-warehouse environments. Real-time data captured through barcode scanning enables businesses to monitor product movement and manage stock levels effectively. This heightened visibility into inventory flow allows for informed decision-making, leading to optimized inventory management and reduced stockouts or overstock situations.

Collectively, these benefits demonstrate how barcode systems can transform multi-warehouse operations, resulting in a more efficient, cost-effective, and customer-oriented logistical framework.

Key Features of an Effective Barcode System for Warehousing

In the context of multi-warehouse operations, an effective barcode system is pivotal for optimizing logistics efficiency and ensuring accurate inventory management. One of the foremost features of such a system is its capability for real-time inventory updates. This feature allows warehouse managers to access current stock levels instantly, which eliminates the discrepancies that often arise from manual inventory counts. The enhanced visibility into inventory status leads to better decision-making and helps in reducing excess stock or stockouts.

Integration with existing Warehouse Management Systems (WMS) stands out as another crucial function of an effective barcode system. A robust barcode system should seamlessly link with the WMS, allowing for synchronized data exchange across all warehouses. This integration is essential for maintaining a unified operational workflow, thus streamlining processes such as order processing, shipping, and receiving. By automating these functions through barcode scanning, organizations can reduce human error and foster operational efficiency.

User-friendly interfaces also play a significant role in the efficacy of a barcode system. The simplicity of use ensures that warehouse staff can quickly adapt to the technology with minimal training. An effective system typically features intuitive navigation, making it easier for employees to perform their tasks efficiently. Additionally, support for mobile scanning devices enhances operational flexibility. This feature allows employees to perform inventory audits and manage stock levels on-the-go, contributing to the agility of warehousing operations.

In conclusion, focusing on key features such as real-time inventory updates, seamless integration with WMS, user-friendly interfaces, and mobile scanning support can significantly enhance the effectiveness of a barcode system in multi-warehouse settings. These functionalities are vital for promoting streamlined operations and ensuring accuracy in inventory management across various locations.

Steps to Implement a Barcode System in Multi-Warehouse Settings

Implementing a barcode system across multiple warehouse locations requires a structured approach that begins with a thorough assessment of current operations. Analyzing the existing inventory management systems is critical to identify inefficiencies and determine how a barcode system can improve accuracy and streamline processes. This evaluation will help in understanding the specific needs of each warehouse site, ensuring that the chosen barcode solution aligns with operational goals.

Once the assessment is completed, the next step involves training staff to familiarize them with the new technology. It is essential that all employees, from warehouse workers to management, understand how to effectively utilize the barcode system. Comprehensive training sessions should cover not only the scanning techniques but also the importance of accurate data entry. This will ensure that inventory records are consistently maintained, reducing the likelihood of errors that could disrupt operations.

The procurement of the necessary hardware is another crucial step in this implementation process. Selecting appropriate barcode scanners and printers is vital; they should be compatible with the existing software infrastructure and capable of handling the specific environments in which they will be used. Consideration should be given to factors such as durability, ease of use, and range of scanning capabilities, ensuring that selected equipment meets the demands of each warehouse operation.

Software integration also plays a key role in facilitating seamless communication between the barcode system and the inventory management software. A coherent integration process will allow real-time data updates, improving tracking efficiency and inventory accuracy. Additionally, establishing best practices for labeling inventory accurately ensures that every item is clearly marked and easily identifiable. This includes defining standard label sizes and formats that can be uniformly applied across all warehouses.

By following these strategic steps, organizations can successfully implement a barcode system that enhances the efficiency and effectiveness of multi-warehouse operations.

Common Challenges and Solutions When Using Barcode Systems

Implementing barcode systems across multiple warehouses can significantly enhance operational efficiency; however, several challenges are often encountered during integration. One prominent challenge is the resistance to change among employees. Staff may be accustomed to existing processes and may feel hesitant to adapt to new technology. To address this, businesses should prioritize comprehensive training programs. By providing clear communication about the benefits of barcode systems—such as faster inventory tracking and reduced errors—employees are more likely to embrace the change and become advocates for the new process.

Another common issue is the occurrence of technical difficulties during the implementation phase. Software compatibility, hardware malfunctions, and network connectivity can hinder the smooth integration of barcode systems. To mitigate these risks, pre-implementation assessments are crucial. Companies should conduct thorough evaluations of their existing infrastructure and perform pilot tests in controlled environments. Furthermore, partnering with experienced vendors can provide access to the necessary technical support. A well-planned rollout can reduce downtime and ensure all components function seamlessly together.

Maintaining system updates and data integrity also poses a significant challenge. As technology evolves, ensuring that the barcode software remains current is vital for optimal performance. Regular maintenance schedules should be established to perform updates and perform audits of data records to prevent discrepancies and errors. Implementing automated systems for monitoring updates can help streamline this process, reducing the manual workload associated with upkeep.

By proactively addressing these challenges through employee training, meticulous planning for technical deployments, and systematic maintenance protocols, businesses can optimize their multi-warehouse operations with barcode systems. The comprehensive understanding and management of these challenges are essential for fully realizing the potential benefits of barcode technology in logistics and inventory management.

Case Studies: Successful Implementations of Barcode Systems

The effective use of barcode systems in multi-warehouse operations has been substantiated by various companies that have navigated their unique challenges to reap significant benefits. This section explores notable case studies that exemplify successful implementations and the transformative impact these systems have had on operational efficiency.

One such example is the international retail giant, Walmart. Faced with challenges related to inventory visibility and management across its numerous warehouses, Walmart integrated a sophisticated barcode tracking system. This implementation enabled real-time inventory updates, drastically reducing stock discrepancies and improving order fulfillment rates. The barcode system streamlined the supply chain processes, allowing Walmart to predict stock levels more accurately. As a result, they achieved a reported 30% increase in overall inventory efficiency, demonstrating how barcode technology can effectively enhance operational performance.

Another significant case involves the pharmaceutical company, Johnson & Johnson. The organization faced stringent regulatory requirements necessitating precise tracking of products in its warehousing system. By adopting an advanced barcode solution, they improved the accuracy of product tracking and compliance with industry standards. The barcode system facilitated faster product recalls and enhanced traceability throughout the supply chain. Consequently, Johnson & Johnson reported a reduction in the time spent on inventory checks by approximately 40%, showcasing the system’s role in boosting staff productivity and operational reliability.

Lastly, a smaller-scale example is provided by a regional food distribution company that struggled with order inaccuracies leading to waste and customer dissatisfaction. After implementing a barcode system, the company noticed a significant increase in picking accuracy, resulting in a 25% reduction in order errors. This improvement not only enhanced customer satisfaction but also contributed to lower operational costs associated with returns and re-shipments.

These case studies illustrate the versatility and effectiveness of barcode systems in overcoming common challenges faced in multi-warehouse operations, ultimately leading to streamlined processes and improved outcomes.

Future Trends in Barcode Systems for Warehousing

The landscape of warehouse management is continuously evolving, driven by advancements in technology and changing operational needs. One of the key trends emerging in this domain is the integration of the Internet of Things (IoT) with barcode systems. IoT enables various devices within a warehouse to communicate with one another, enhancing visibility and control over inventory management. For instance, smart shelves equipped with sensors can automatically update stock levels in real-time, ensuring that barcode scanning is aligned with actual inventory data, thereby reducing discrepancies.

Additionally, Radio-Frequency Identification (RFID) technology is gaining momentum as a complementary tool to traditional barcode systems. Unlike barcodes, RFID tags do not require direct line-of-sight for scanning, which allows for faster and more efficient inventory tracking. As RFID technology becomes more cost-effective and widely available, warehouses are likely to adopt these systems to enhance their operational efficiency. The integration of RFID with existing barcode systems streamlines processes, allowing for bulk scanning and reducing the time spent on inventory counts.

Another significant trend is the utilization of data analytics in conjunction with barcode systems. As warehouses continue to collect vast amounts of data from their barcode scans, advanced analytical tools are necessary for interpreting this information. By leveraging data analytics, warehouse managers can gain valuable insights into inventory turnover rates, identify slow-moving products, and optimize storage solutions. This data-driven approach leads to more informed decision-making and can significantly enhance overall warehouse productivity.

As we look to the future, the collaborative interplay between IoT, RFID, and data analytics will redefine barcode systems in warehousing. Businesses that proactively embrace these technologies will be better positioned to enhance their operational efficiency and effectively respond to the growing demands of logistics.

Conclusion and Final Thoughts

In today’s fast-paced supply chain environment, optimizing multi-warehouse operations is paramount for enhancing overall efficiency and accuracy. The use of barcode systems has emerged as a transformative solution to meet these operational challenges. Throughout this discussion, we have underscored the various benefits that barcode technology brings to warehouse management. From improving inventory tracking to streamlining order fulfillment processes, barcode systems facilitate real-time data capture that reduces human error and increases productivity.

Implementing barcode systems is not merely a technological upgrade; it represents a strategic shift toward more robust operational practices. Organizations that adopt this technology can expect significant improvements in tracking items across multiple locations, ultimately leading to better decision-making. Additionally, the integration of barcode systems with existing warehouse management systems enhances the visibility of inventory levels and reduces the risks associated with stock discrepancies.

Furthermore, the adaptability of barcode solutions allows businesses to tailor the system to their specific requirements. Whether dealing with varying product types, diverse storage configurations, or fluctuating demand patterns, barcode systems can be customized to provide the necessary support for an efficient workflow. This adaptability is particularly crucial for companies operating in multiple warehouse environments, where coordination and accuracy are key to maintaining a competitive edge.

As companies look toward the future, considering the implementation of barcode systems should be a priority. By leveraging this technology, businesses can not only optimize their multi-warehouse operations but also position themselves for long-term success. In summary, the integration of barcode systems into warehouse management practices is a vital step toward achieving greater efficiency, accuracy, and ultimately, operational excellence.

© barcodly.com- All rights reserved